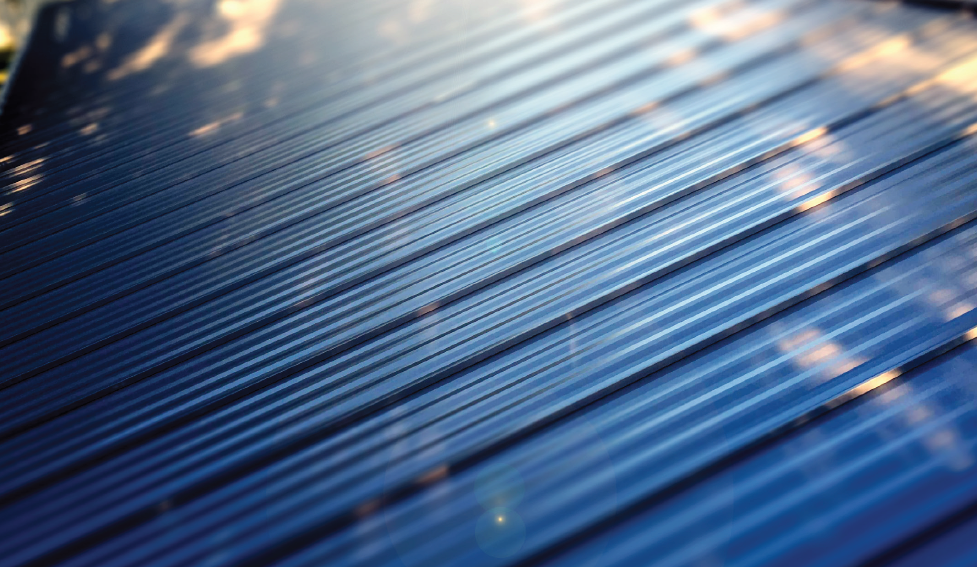

The roofing system called standing seam roofing is the most reliable roofing system in terms of water and thermal insulation. As no screws are used at the seams, it is completely waterproof. In the simplest sense, it is created by applying insulation material between two plates and seamed by folding the upper plates on each other. Rockwool is generally used as thermal insulation material. A line is formed for the thermal insulation material by placing Z profiles on the bottom plate. In the coating system, the bottom plate can be chosen as trapezoidal or OSB. Before the top sheet is seamed, a geotextile mattress, a.k.a. a moisture barrier, is installed, which eliminates moisture and perspiration.

Standing seam roofing can be applied with thermal insulation filling or without filling and using only OSB, moisture barrier and seam sheet. Since it is rolled in a rolling mill by forming ribs from the rolled sheet, it can be installed

as a single piece even in very large openings without creating a vertical seam detail. Horizontal seams are seamed by folding on each other. It is generally applied as a roof system or can be applied as a wall system by rolling the material vertically. A smooth coating surface can be created by using thin OSB or corrugated sheet for vaulted roofs with high inclination and inclined surfaces. Since no screws are used in the seams, it is completely waterproof.

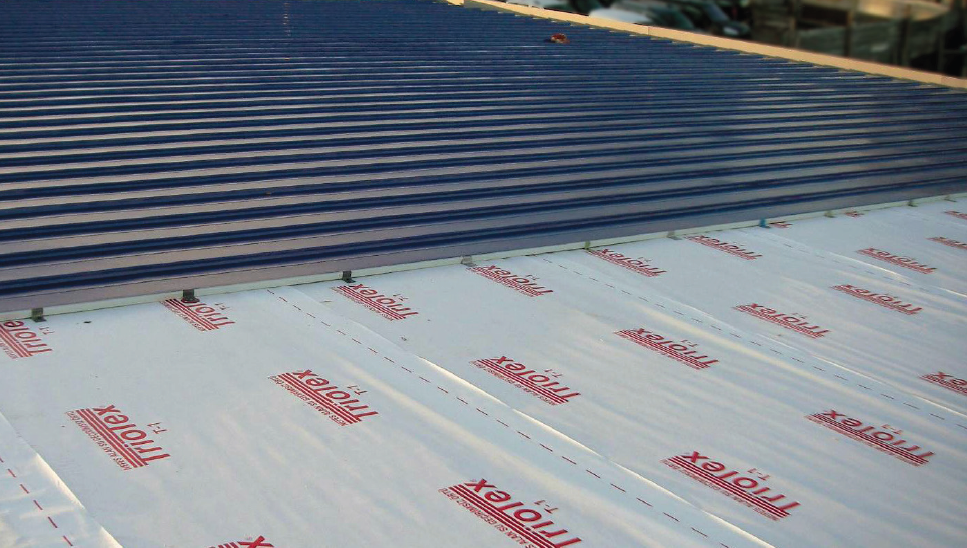

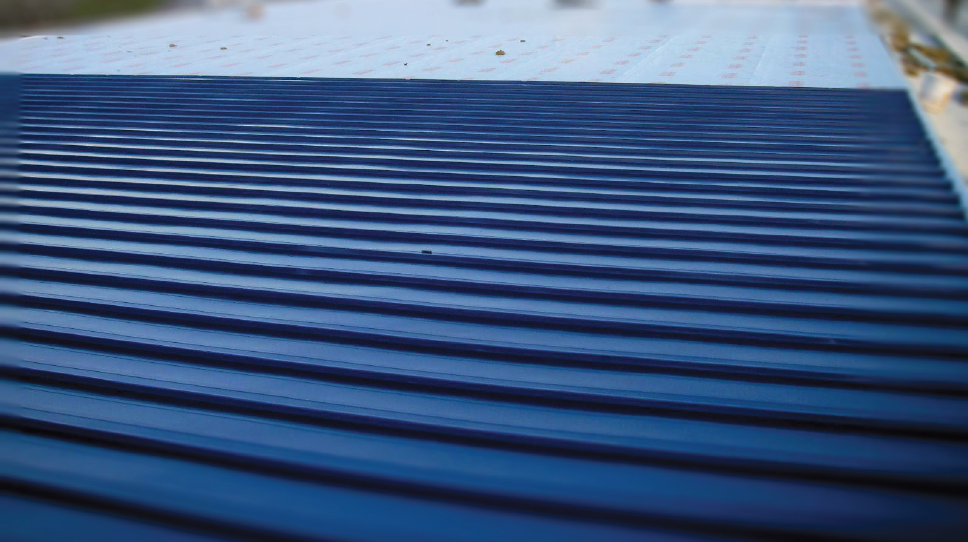

(Standing seam roofing application, example 1)

(Standing seam roofing application, example 2)